At Excellent Systems we have always strived to impact our environment as little as possible, through sustainable production and the use of non-toxic materials. Our focus on recycling resources and reducing waste permeates all of Excellent Systems' work and values.

There are many benefits to sustainable production, and both resources and money to save. Over the years, we have managed to recycle almost everything from our daily production. We usually say that the only waste we have is what comes from the canteen. Back in 1992, we started using the cooling water from our production machines to heat our offices. In this way we save water, electricity and heat.

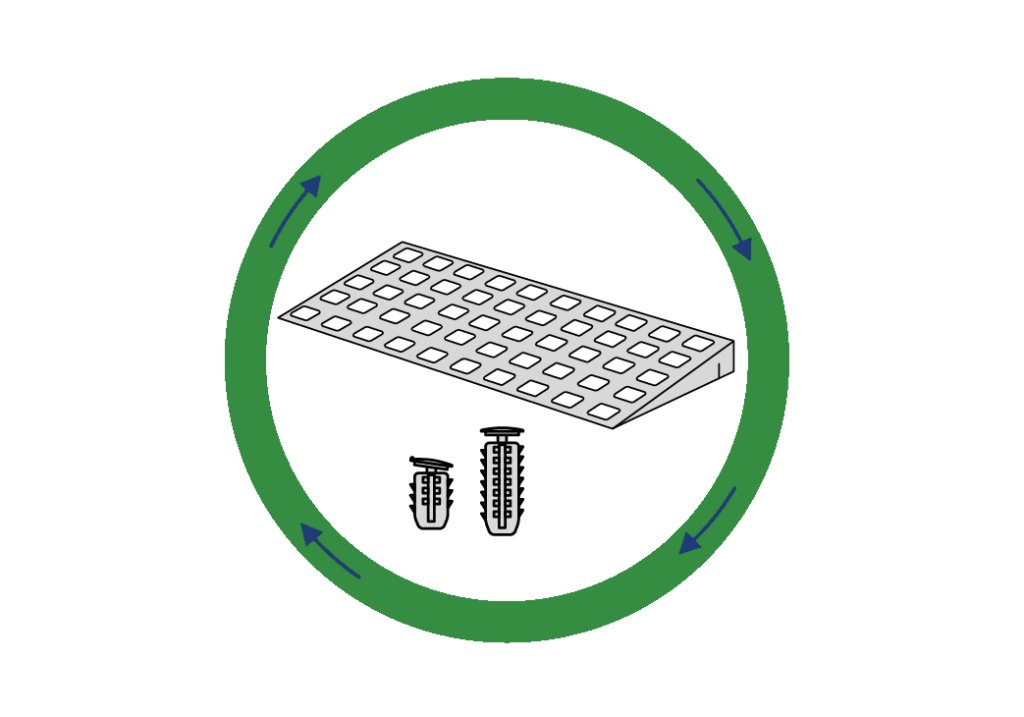

The circular economy does not only benefit our company. Our customers also save money by sending end-of-life products for recycling. In fact, we give a cash discount on the next order, based on the number of kilograms of recycled plastic we receive. We call this program Cradle to Cradle.

Vi har et medansvar for vores medarbejderes sundhed og trivsel og det tager vi seriøst og har derfor bl.a. sundhedsforsikringer og pensionsordninger. Vi har fokus på at styrke den generelle sundhed og trivsel på arbejdspladsen – bl.a. med daglig morgengymnastik og forskellige sociale arrangementer. Derudover støtter vi økonomisk Røde Kors, Kræftens Bekæmpelse og de Danske Hospitalsklovne.

Hos Excellent Systems A/S sikrer vi, at kvinder og mænd har de samme rettigheder og muligheder og har naturligvis nul-tolerance overfor mobning og sexchikane. Vi prioriterer at forebygge enhver form for diskrimination og vold i vores virksomhed og at der ydes kyndig vejledning, hjælp og støtte, hvis behovet skulle opstå.

Vi effektiviserer vores produktion med brug af robotter til de tungeste løft og de mange gentagende bevægelser og aflaster dermed medarbejderne og gør arbejdet mere skånsomt. Der arbejdes ligeledes med anvendelse af exo-skeletter til de arbejdsopgaver, som belaster mest. Vi har altid haft stort fokus på at kunne rumme folk i f.eks. Fleksjob, og derfor har vi pt 3 medarbejdere ansat under den ordning, til glæde for dem, samfundet og os.

Verdensmål 12 er en ufravigelig del af Excellent Systems DNA, vi har siden 1992 arbejdet med konceptet ”vugge-til-vugge” på vores egne produkter og vi har opnået at genanvende vores udtjente produkter i en bæredygtig proces i stedet at de ville ryge til forbrænding eller på lossepladsen. Det hele med et stort fokus på at bruge så lidt unødvendig CO2 som overhovedet muligt. På fabrikken affaldssorterer vi i så stor en grad, at vi ikke sender mere til deponering end en gennemsnitshusstand i Danmark.

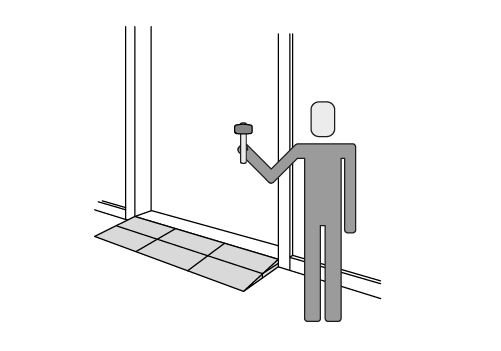

We focus on improving accessibility for people with motor impairments and walking disabilities and helping them participate on an equal footing with everyone else in the workplace and in public spaces.

We are continually working to make our products more environmentally friendly and are leading a closer collaboration with municipalities across the country. Together, we collect end-of-life products as part of our ability to recycle them to reduce the environmental impact on private and public facilities and improve overall access to green and public spaces with limited mobility.

FN har sat 17 verdensmål, som lande og virksomhederne skal arbejde for at beskytte og forbedre tilværelsen for mennesker, dyr og på klodens ressourcer. Målene er sat til 2030 hvor de forskellige institutioner arbejder for at opnå.

Vi har valgt at fokusere på 4 af de 17 verdensmål men arbejder løbende for at indfries de andre verdensmål både direkte og indirekte tiltal. Vi mener at vi har et ansvar om at mindske aftrykket på naturens ressourcer samt forbedre tilværelsen i lokalt og på verden

Du kan læse mere om de 17 verdensmål hos FN verdensmål: https://www.verdensmaalene.dk/fakta/verdensmaalene

We share responsibility for the health and well-being of our employees and take this very seriously. That is why we have taken out health insurance and pension insurance for our team. Strengthening general health and well-being at work is a top priority for us - including daily morning gymnastics and various social events. We also financially support the Red Cross, the Danish Cancer Society and the Danish Hospital Clowns.

At Excellent Systems A/S, we ensure that women and men have the same rights and opportunities and, of course, have zero tolerance for bullying and sexual harassment. We make it a priority to prevent any form of discrimination and violence in our company and to provide expert guidance, help and support should the need arise.

Our production is so efficient because we use robots for the heaviest lifting and many repetitive movements, thus reducing the workload on the labor force and making the work more gentle. We are also working on the use of exo-skeletons for the most demanding tasks. Furthermore, we have always placed great emphasis on accommodating people in Flexjob, and therefore currently have three employees who are employed under this program, which benefits them, the company and us.

SDG 12 is an integral part of Excellent Systems' DNA. We have been working according to the principle of circular economy for our own products since 1992 and have managed to recycle our end-of-life products in a sustainable process instead of incinerating or landfilling them. Care is taken to use as little unnecessary CO2 as possible. At the factory, we sort the waste so that we do not send more to landfill than an average household in Denmark.2 as possible. At the factory, we sort waste to such an extent that we do not send more to landfill than an average household in Denmark.

We focus on improving accessibility for people with motor impairments and walking disabilities and helping them participate on an equal footing with everyone else in the workplace and in public spaces.

The UN has set 17 Sustainable Development Goals (SDGs) that countries and businesses must work to protect and improve the lives of people, animals and the planet's resources. The goals are set to 2030 where the various institutions are working to achieve.

We have chosen to focus on 4 of the 17 SDGs, but are continuously working to achieve the other SDGs both directly and indirectly. Our belief is that we have a responsibility to reduce the footprint on natural resources and improve lives locally and globally.

You can read more about the 17 SDGs at UN SDGs: https://www.verdensmaalene.dk/fakta/verdensmaalene

We are continually working to make our products more environmentally friendly and are leading a closer collaboration with municipalities across the country. Together, we collect end-of-life products as part of our ability to recycle them to reduce the environmental impact on private and public facilities and improve overall access to green and public spaces with limited mobility.

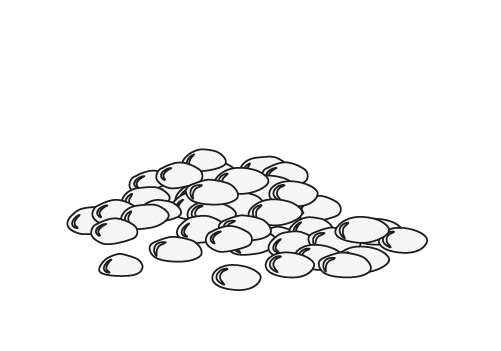

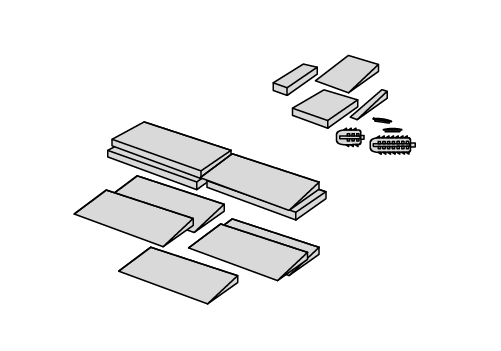

Commodities

All our products are made of non-toxic Polyethylene (PE), plastic granulate. It is the same environmentally friendly material found on the inside of milk cartons and is approved for food use.

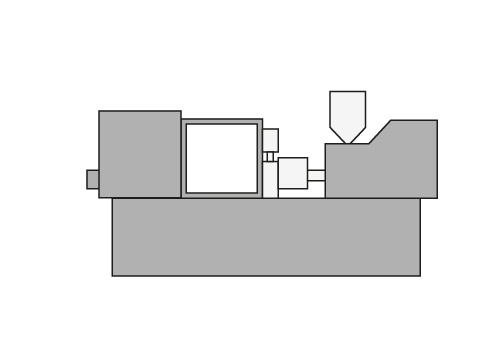

Production

All our products are designed by Director Ole Frederiksen. They are produced in our factory near Mørke, and shipped to customers all over the world. Danish design, Danish quality, Danish production.

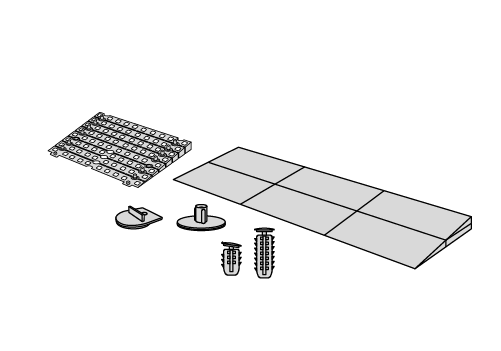

Products

Through injection moulding, we can produce the many different elements for our ramp and tile systems. By producing them locally, we ensure that quality and safety are always top notch.

Montage

We carry out assembly work throughout Denmark, and always ready for advice and guidance. For international customers, we have selected dealers worldwide who we train in the proper sale and installation of our products.

Profits from adjustment

During assembly, excess material often occurs after adjustment. We take this material back to the factory where it is recycled again to reduce waste of good resources.

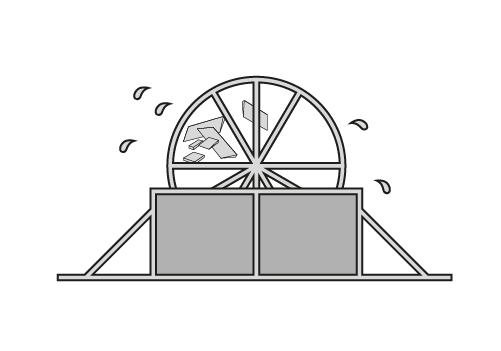

Wash

Used parts and excess material from assembly are washed in our CO2 neutral washing machine to remove any dirt and grime. The machine uses rainwater and green power.2.

Crushing and regeneration

The clean plastic is then ground into plastic granules. It's a simple process that makes it easy to recycle the plastic in our injection moulding machines. The granulation is carried out at the factory.

New products are ready!

The regenerated plastic granulate is now ready to be used in our production. The sustainable recycling process has ensured that the quality of the plastic is as good as new plastic. No waste, only good plastic!

Non-toxic PE plastic

All Excellent Systems products are produced from non-toxic polyethylene – PE. Some products are made of PEHD, which means High Density and is hard plastic. Others are made of PELD, which is Low Density and a softer plastic.

Strong products

PE products are strong and can bear weight up to 2,000 kg. You can therefore use all kinds of wheelchairs and walking frames on the products and even drive your car over them, if the product e.g. located in your driveway.

Abrasion resistant surface

Our ramp systems have non-slip surfaces. If the product is to be used in wet areas or other challenging environments, we recommend an additional purchase of our SlipStop, which is extra slip-resistant.

Non-toxic in case of fire

PE plastic is environmentally friendly, according to DTU studies. They have shown that the plastic does not emit dangerous and toxic gases in case of fire, as many other ramps made of rubber, for example, do.

Varying temperatures

All our products can handle temperatures from -50C up to +100C. You can therefore safely use our many solutions in the vast majority of weather and working situations, without fear of the product breaking.

Corrosive agents

PE products are acid-resistant and corrosion-free, and can withstand all kinds of common cleaning agents. The elements can be cleaned with e.g. a high-pressure cleaner or, if possible, in a normal dishwasher.

Excellent Systems A/S • Møllevej 2 • DK - 8544 Mørke • +45 8637 7133 • sales@ex-as.com • VAT: DK25276183

Copyright 2023 © All Rights Reserved. Excellent Systems A/S