Our GRIP range has been specially developed for work areas with slippery surfaces, such as with drilling mud, cutting fluids, silicone, oils and grease, soap.

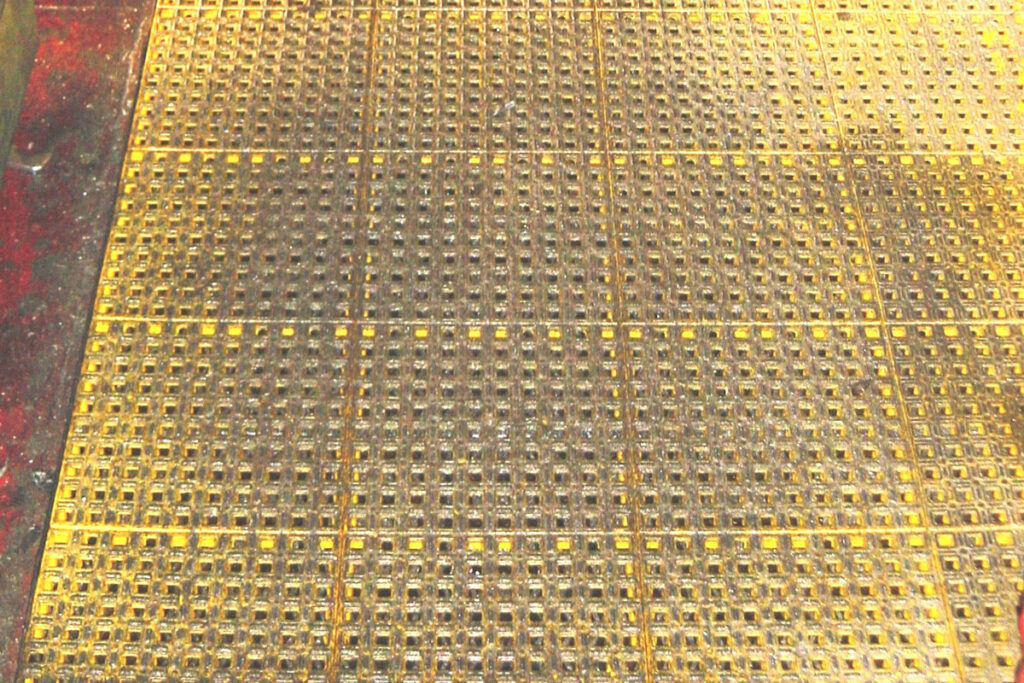

The GRIP system is a unique floor system of tile modules equipped with anti-slip spikes, which ensure a good foothold in slippery and greasy environments. At the same time, the system is extremely resistant to aggressive liquids such as acids.

The tiles are easy to install thanks to their click function, where you can lay the tiles one after the other and adapt them to the surroundings. The tiles can be installed both inside and outside and are easy to clean with a high-pressure cleaner.

The GRIP system is suitable for pedestrian areas, but cannot be used for heavy traffic. If you want to drive in the area, we recommend that you combine our GRIP tiles with our HARD tiles.

We focus on improving the workflow in greasy areas where people move and need to be able to stand safely on slippery floors. Ordinary floors without a slip-resistant surface are a slippery surface for those who move around on them. When there is nothing that can provide a foothold, such as with drilling mud, it can lead to falls and injuries. This is where our GRIP system comes into the picture. Our GRIP tiles are easy to install and can be laid out in areas where employees move. Spikes on the tiles ensure that the foot sticks to the surface, and any liquids can run down the holes in the tiles.

Our GRIP tiles comply with DIN standard 51130 and are rated R12, which is the second highest anti-slip rating.

GRIP – for your safety!

Before

After

It can be used even in extreme environments, e.g.

• Drilling mud

• Oil

• Grease

• Cutting fluids

• Hydraulic fluid

• Brake fluid

• Silicone

• Salt water

• Green algae

• Soil and mud

It is a great advantage of Excellent-System's products that 1 m² consists of 16 tiles, which means that not need to replace the entire surface, but only the worn or damaged tiles.

The coupling system in our tiles makes it easy to replace individual tiles or strips of tiles. You just have to grab the individual tile, pull it up and put a new one down in the couplings. If it is a whole row that needs to be changed, you simply pull the strip up and put a new strip down.

Especially when it comes to GRIP tiles, it is crucial to ensure slip resistance, especially under demanding conditions. It is therefore important to take into account that there will be a need for ongoing maintenance and replacement of tiles to maintain safety.

It is therefore a good idea to draw up a maintenance plan for the individual installation.

GRIP floors made of PEHD can withstand cleaning with all known cleaning agents, including common acids and bases, high-pressure cleaning and hot water cleaning. The tiles can also withstand cleaning in dishwashers and autoclaving with steam at 130 °C.

If you have any questions regarding the quantity or the process of the installation, please feel free to contact us. We are ready to help you from ordering to installation, so you get the best result. If you are planning a project and want to hear about our offer, contact us so that together we can find a solution to create better working conditions for your colleagues. We are specialists in installing floors in industrial areas where there is a risk of slippery and slippery work areas.

Contact us for an offer on your anti-slip floor.

Use our contact form or call us on 86 37 71 33.

Excellent Systems A/S • Møllevej 2 • DK - 8544 Mørke • +45 8637 7133 • sales@ex-as.com • VAT: DK25276183

Copyright 2025 © All Rights Reserved. Excellent Systems A/S